Royeshgar Cabin Dryer

These dryers can be used for all kinds of vegetables and fruits. Royeshgar fruit and vegetable dryers, which are used for domestic and industrial purposes, increase the shelf life of the final product and reduce humidity by drying the product. The process of drying food is done to an extent that limits microbial growth and chemical reactions.

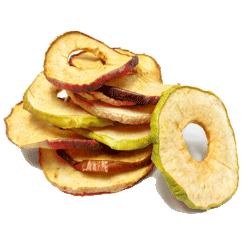

To prepare dried fruit and vegetable, they must first be washed, then sliced and arranged in the machine’s trays. In this device, the temperature required for drying is entered into the system by the blower, and it is available to you in a much shorter period of time compared to the traditional system of dried products.

The Royeshgar dryer machine has a heating system with a gas burner, and in terms of energy consumption, it is superior to the fruit and vegetable dryers available in the market.

Industrial production of food has always been of interest due to mass production, but in some cases, domestic production has advantages compared to industrial production, including more monitoring of the production stages, compliance with health issues, and not adding preservatives or special additives.

• The heating energy produced by the device is through the consumption of natural gas and it is possible to electrify it according to the customer’s order.

• It has an intelligent control system to adjust the time, temperature, and humidity of the cabin.

• It is possible to customize the dryer according to the customer’s request.

View the royeshgar dryers

No videos found

Important Points …

1how long does it take to dry the products?

Basically, fruits have a moisture content of 85%, which means that from every 100 kilograms of incoming products, about 15 kilograms of dry products can be produced. The time required to dry them depends on the temperature you choose. In addition, the structure of the fruit is directly related to the drying time. For example, the texture of plum and orange is very different. Vegetables also have an approximate moisture content of 90%, which means that from every 100 kg of input product, approximately 10 kg of dry product can be produced. (To complete the information of this question, get the electronic article on how to dry products from the company’s consultants

2How is the production capacity of dryers calculated?

The introduced capacities are maximum and volumetric mass or scientifically (Q=m/v), for example, a vegetable has a large volume if it weighs much less, or for dried fruit, it is possible to significantly increase the production volume by changing the thickness of the product slice. For example, slicing a 4 mm product with 6 mm and 8 mm will increase by 50% to 2 times. But the best solution is to pay attention to the number of trays and their dimensions in terms of length, width, and height.

3How to ensure the drying of a high-quality product?

During the experience of drying fruits and vegetables, the most important criterion for drying the product is temperature and time. Product drying standards with research and experiences of our customers all over Iran are available in the article on how to dry, which shows you the approximate timing and is the best solution to get a product with the quality of your personal experience. (Note: to gain experience, use a device with a lower capacity next to your production line, and if your production capacity is low, try to test a sample of the desired product before buying a large number of raw materials, for example, chips Apples are produced a lot, and this is despite the fact that more than 30 tree apple varieties have been identified in Iran so far, and this means care before production.

4 Is it possible to produce all kinds of products at the same time?

Considering that the designed device has the possibility of drying solid products with moisture, it is possible to produce products at the same time, but we recommend that you do not dry different products at the same time. Because the drying time of the products is different from each other and also the smell of moisture evaporation has a direct effect on other products and finally, your product will be of lower quality than competitors. (Refer to the product drying schedule article or get help from Roishgar consultants) To dry the product at the same time for factories, it is possible to divide the machine and use separate spaces. (Note: after drying some products, it is better to turn on only the fan or forwarder for a period of time to eliminate the smell)

5Is it possible for the product not to dry or semi-dry?

The use of indirect heat in order to use minimum energy and ultimately produce a very high-quality product in cabinet dryers requires the precise design and construction of the entire system. Because the temperature is produced in another environment and is directed to the dry chamber by ducting, in this part the input temperature is divided and the desired heat enters the system through the perforated sheets and after coming into contact with the sliced fruits and Vegetables come out with moisture. Now, in some devices, due to the strengthening of the furnace and heat transfer system, which may be suitable for your order and for the future and to improve the production rate, it does not match the output of the device (the output of the dry chamber can be seen from both the upper and lower parts of the back of the device and a brief explanation is given in this booklet) or that the piping of the outlet of the chamber is reduced and the temperature output along with the humidity becomes hard. In such a situation, which is also called a temperature vortex, the system may experience a dry blind spot at some points, especially at the exits of the chamber, at the corners, or even at the trays that are stuck together in larger dryers. In the worst case, about 10-15% of the semi-dry production is left, and this is a completely normal thing, and you can put the desired product again in the next shift, change the location of these trays, or spend a little more time drying. Assign them. But if the semi-drying of the products in the container is more than this percentage, immediately contact the after-sales service of the company so that an expert force will be sent to your place to solve the problem